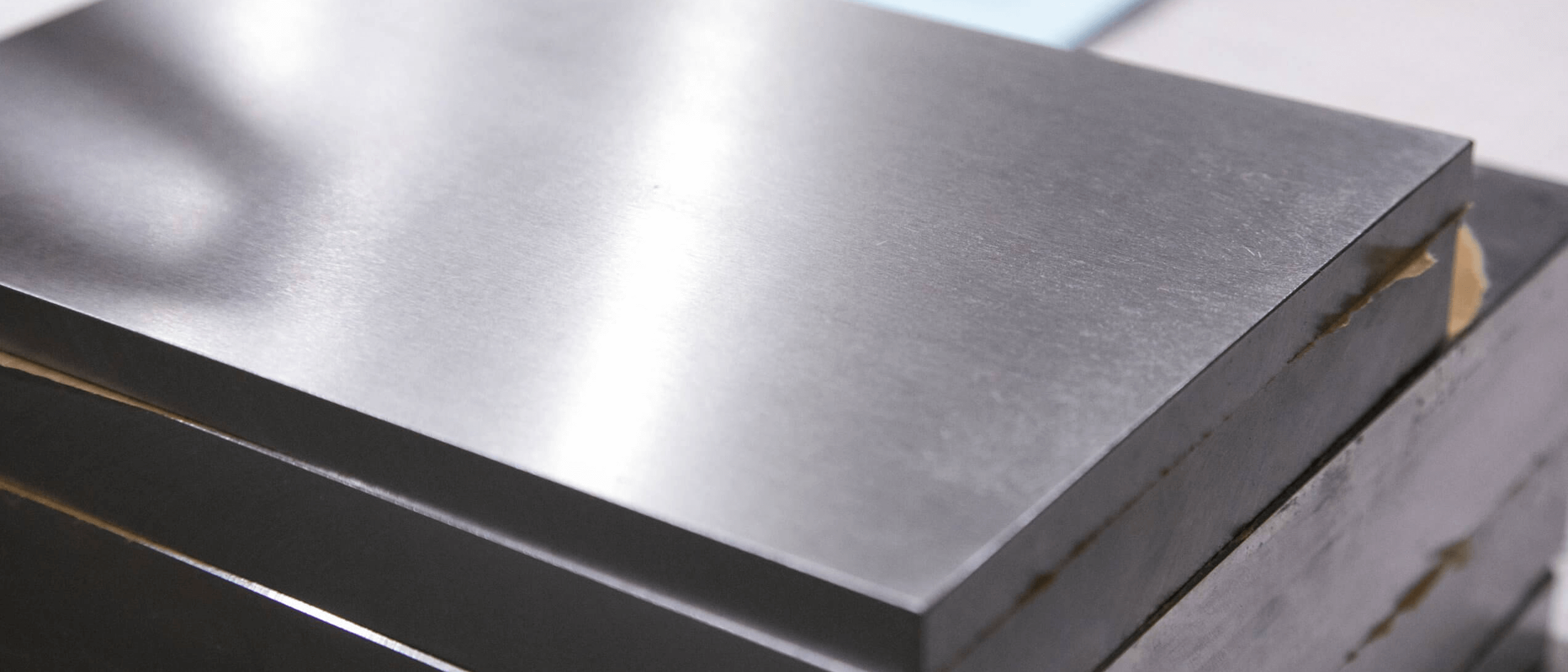

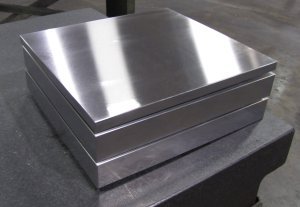

Precision Grinding

Precision surface grinding is a method used to achieve a high level of flatness and smoothness on the surface of steel. It involves using a grinding wheel to remove small amounts of material from the surface, creating a precise and uniform finish.