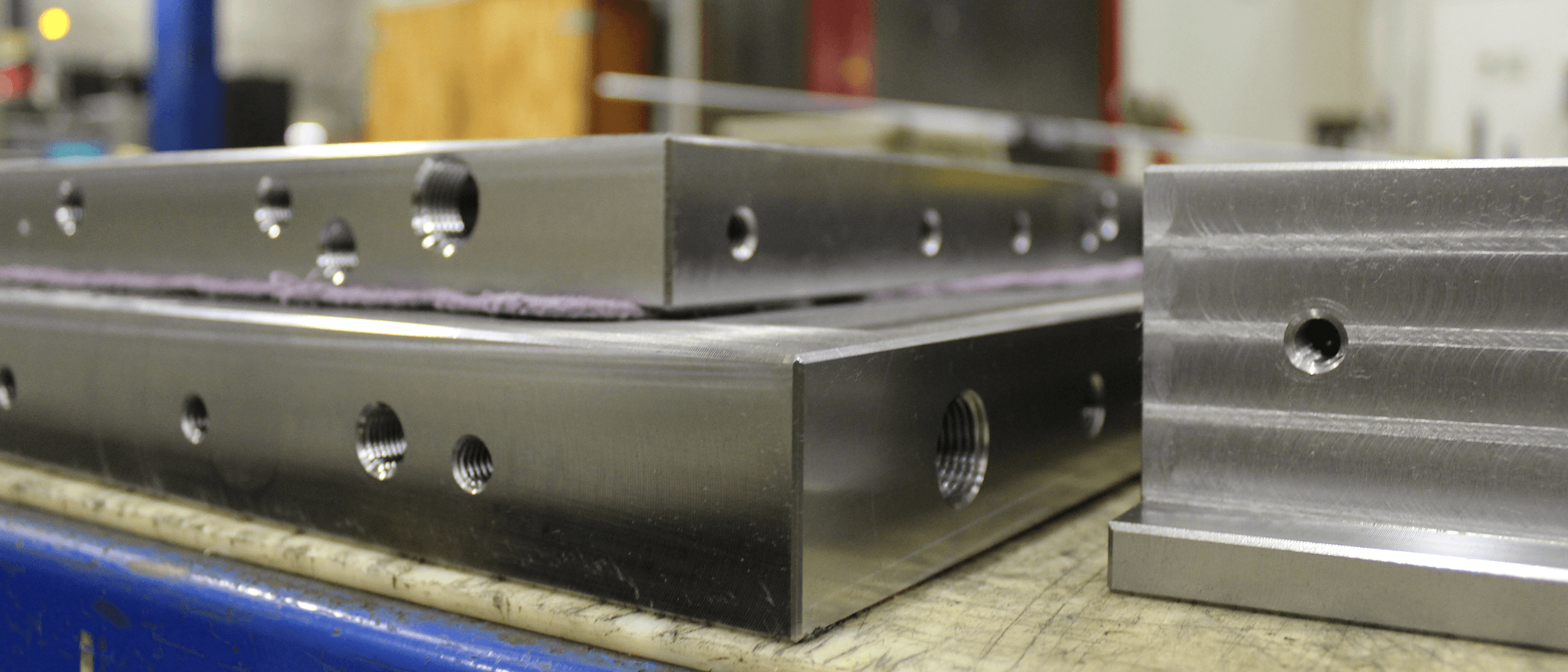

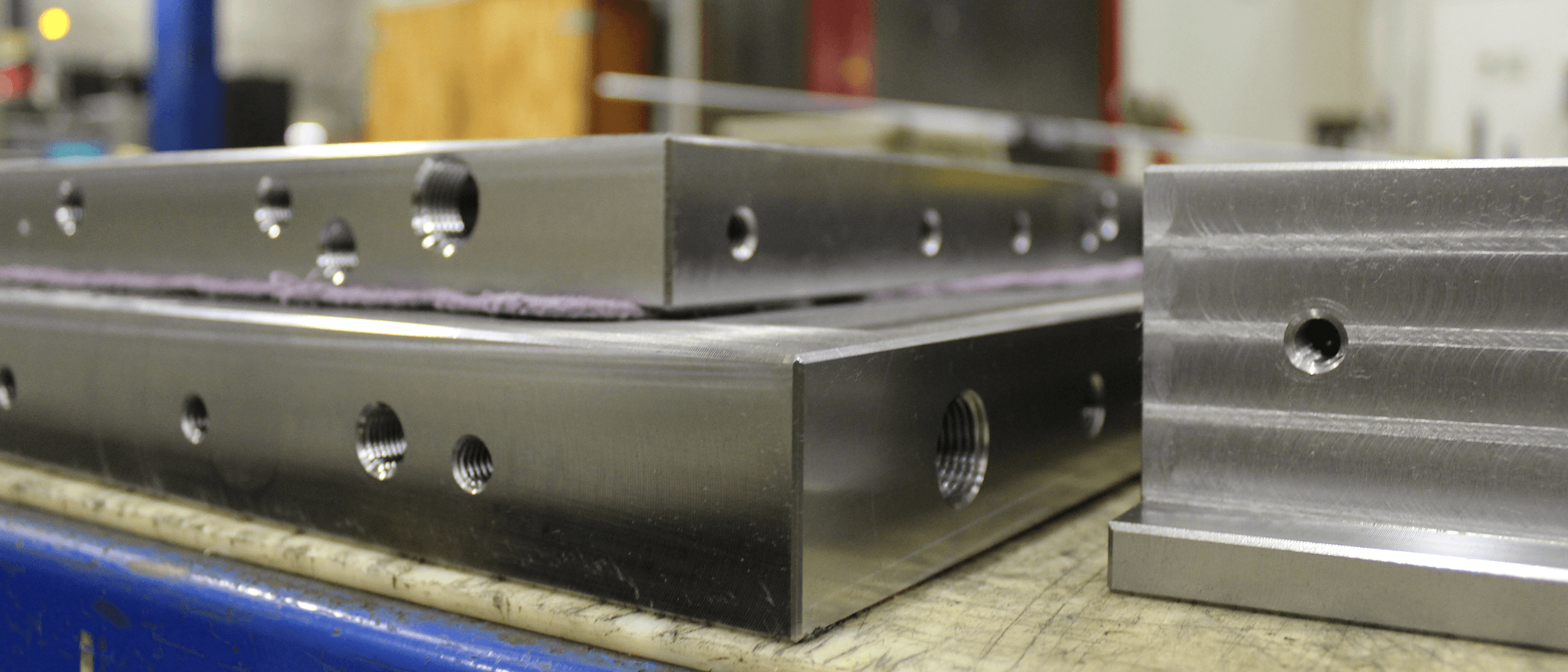

Gun Drilling

Gun drilling is a specialized process that allows a through coolant drill to drill a long straight hole. Benefits of gun drilling include straightness (minimal drift) and close tolerance of the hole.

Gun drilling is a specialized process that allows a through coolant drill to drill a long straight hole. Benefits of gun drilling include straightness (minimal drift) and close tolerance of the hole.