Blanchard Grinding

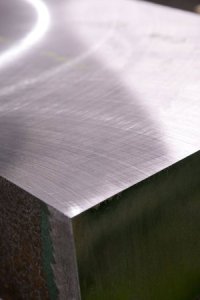

Blanchard grinding is a grinding process typically used for large, flat parts or plates that require significant material removal and a precise, uniform surface finish. Named after the Blanchard Machine Company that developed it, the process is known for its distinctive cross-hatched or swirled pattern on the ground surface.

Key Aspects of Blanchard Grinding

- Process: Blanchard grinding involves using a large, rotating circular magnetic chuck to hold the workpiece in place. The grinding wheel, which also rotates, is mounted above the workpiece, and both the chuck and wheel spin in opposite directions. This rotation allows for even material removal, and the pattern results from the grinding wheel’s circular motion.

- Advantages:

- High material removal rate: It’s much faster than other grinding methods, especially when working with large parts.

- Uniformity: Provides a consistent and uniform finish across the entire surface of the part.

- Cost-effective: Often more economical than other finishing processes for large parts because of the high-speed material removal.

Blanchard grinding is widely used in heavy-duty manufacturing sectors such as automotive, construction, and aerospace, where large parts or high-tolerance flat surfaces are necessary.