Duplex Milling

Duplex Milling

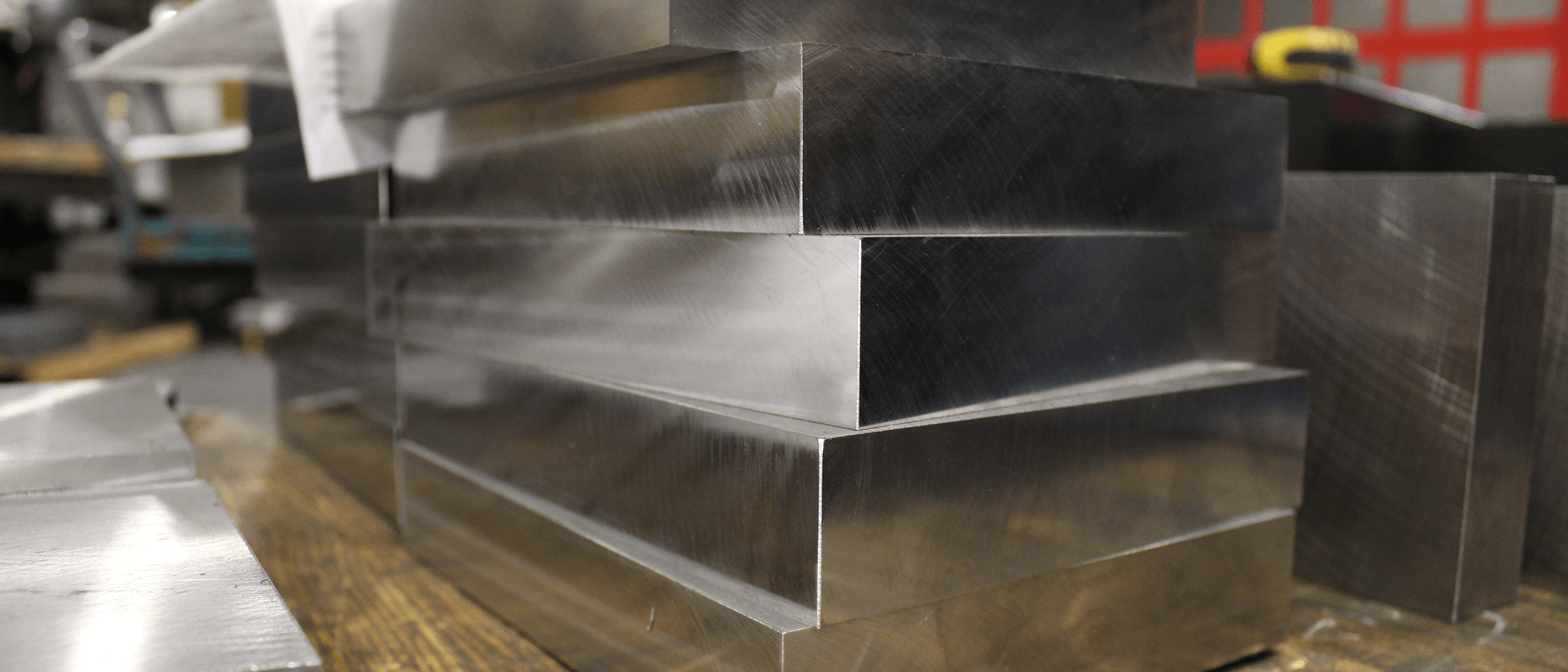

Duplex milling is a machining process used to remove material from both sides of a workpiece simultaneously. This is achieved using two cutters or milling heads positioned on opposite sides of the workpiece. Duplex milling is particularly efficient for creating a high degree of parallelism and flatness, making it ideal for applications where precision flatness and squareness are critical, such as in the manufacturing of large metal plates, bars, and other flat components.

Key Aspects of Duplex Milling

- Process:

- Two milling heads operate on opposite sides of the workpiece, often mounted on a specialized machine designed for this purpose. Both heads work simultaneously, removing material from each side, which cuts down on machining time.

- The workpiece is securely clamped to ensure it remains stationary while the cutters mill both sides evenly, ensuring precise parallelism.

- Advantages:

- Time efficiency: Since both sides are milled simultaneously, duplex milling drastically reduces the overall machining time compared to single-sided milling processes.

- Precision: Duplex milling produces parts with highly accurate parallel surfaces, as both sides are milled in one setup, reducing the need for multiple machine alignments.

- Consistency: This process offers high repeatability and uniformity, which is beneficial for mass production of flat components with tight tolerances.

Max Dimensions: up to 16.90″ x 16.90″